2020-08-08

2020-08-08 Longan Nano GD32VF103 Demo

>>>Longan Nano GD32VF103<<<

>>>Longan Nano Demo<<<

1Longan nano GD32VF103 Demo

I built Display, Screen and Chrono class drivers for the Longan nano GD32VF103 board.

This Demo application is meant to show off the features of the drivers and jump start the development of the application.

I spent extra effort in testing and documentation to make sure the drivers are as stable as possible since they are going to be the building blocks for all my future applications on this board.

1.1Chrono Class Driver

The Chrono class uses the 64bit 27MHz@108MHz CPU clock timer to provide accurate timings.

Time units are defined in the Longan_nano::Chrono::Unit enum.

The Chrono class has two modes of operation:

start/stop elapsed timer: measures DeltaT

start/accumulate: integrate a DeltaT on an accumulator

Those two modes of operations can be used to profile uptime, elapsed time, time spent running code and more.

1.2Display Class Driver

The Display class interfaces directly with the LH096T ST7735S 0.96 inches 80x160 oled color screen.

The library uses the .init method to initialize the display has two modes of operations:

register_sprite/update for asynchronous non blocking operations.

draw_sprite for synchronous blocking operations.

The Display class uses optional DMA acceleration and the SPI0 and a few GPIOs to communicate with the physical screen.

The Display class does not use interrupts. While using interrupts can make the driver transparent to the user by automagically calling the update method, it can interfere with other real time operations. As design philosophy, the driver is meant to be secondary to the application and meant to show information, giving the application control over the amount of resources used by deciding the call speed of the update method. Calling .update() every 100us will result in about 1250 sprites updated per second. If the user makes more print calls than what the display can handle, the display will simply ignore older calls displaying the most recent sprite. At top load a refresh rate of about 1250/100=12.5 frames per seconds can be expected. The refresh rate becomes 1.25 fps at full load if .update() is executed every 1000us instead of 100us.

1.3Screen Class Driver

The scope of the screen class is to support ascii print of fixed size on fixed grid, and is meant for the common use case of showing debug and runtime number of the application.

The Screen class add a sprite based abstraction layer with print to reduce the size of the frame buffer and CPU use. It also provides a large number of overloaded print methods. The Screen class inherit the Display class, allowing to decouple the physical screen from the print implementation and simplify a move to a bigger screen if needed.

The Screen class supports two ascii fonts. 8x10 Courier Now and 8x16 NSimSum that can be toggled by setting the define FONT_HEIGHT and recompiling, the smaller font shows 8x20=160 sprites on screen, while the bigger font shows 5x20=100 sprites on screen and is easier to read.

2DEMOS

There are ten demo, showcasing the use of the print and timing functions to display an HMI.

Clear the screen to a random color every 500ms

Print a random character in a random position of the screen every 1ms

Same as above but with random foreground and background colors

Print a random string in a random position of the screen every 25ms

Same as above but with random foreground and background colors

Print numbers with right and left adjust

CPU execution and uptime with engineering format 4 significant digit and SI suffix

Same as above but with screen builtin pending and error methods

Same as above but with random foreground and background colors

Constant workload demo. Print 10 sprites every 25ms and show CPU use

Illustration 1 - Demo

3Documentation and Style

I made a point to learn more C++ features, with this project I elected to use .hpp files with header and implementation together since inline needs to be declared alongside the header anyway. I also experimented with scoping of typedef and enum to allow the same enum name to be in multiple libraries without conflicts.

I also integrated the Doxygen documentation style comments and generated the automatic documentation, as well as integrating the documentation alongside the code repository in GitHub.

The same style is going to be used for my next classes and drivers.

4Conclusions

I begun this project to learn a Risc-V MCU. The Longan Nano Demo provides an example application for the scheduler, Chrono, Screen and PA8 button, and can be used as a base to develop applications with the Longan Nano GD32VF103.

I am satisfied with the performance, and how the drivers have turned out. The board provides great value, and in my opinion is held back by the poor examples. Hopefully more people will adopt the Longan Nano and help in building libraries and example code to make it easier to develop applications on Risc-V MCUs to come.

The first application of this MCU will be as new motor controller for OrangeBot.

5Source Code

5.1Doxygen Documentation

5.2Source Code

>>>Screen and Display classes<<<

2020-08-03

2020-08-02 Longan Nano GD32vf103 Display and Screen Classes

>>>Longan Nano GD32VF103<<<

>>>Longan Nano Screen and Display Classes<<<

1Longan Nano GD32VF103 Display and Screen Classes

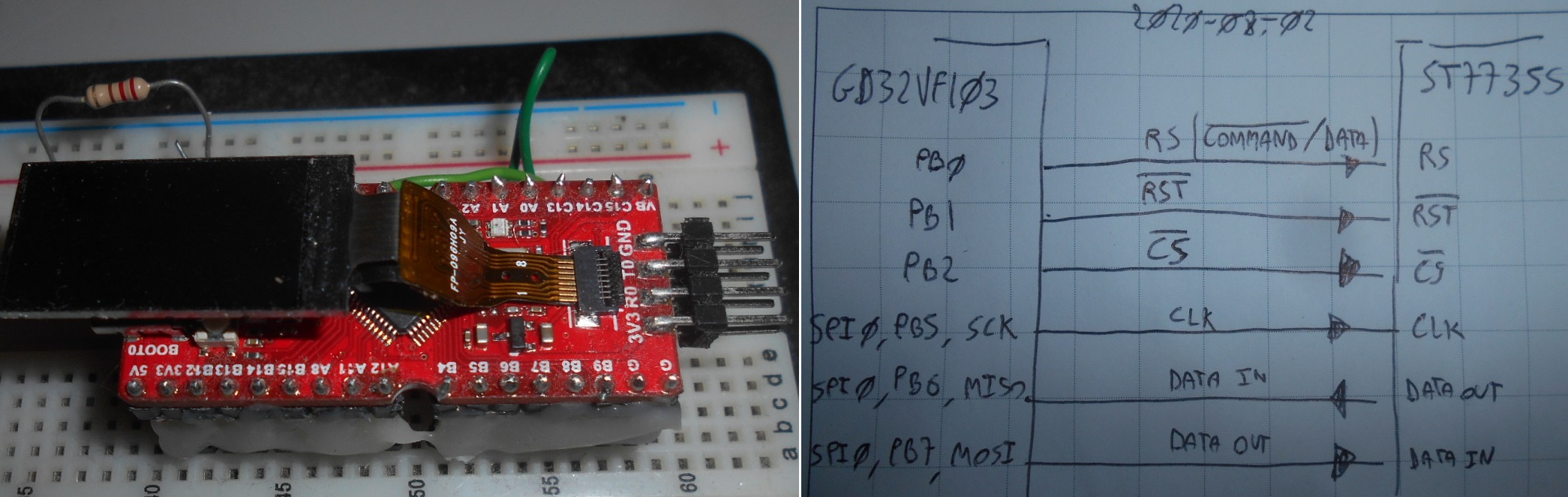

The Longan Nano is equipped with an OLED 0.96 inches 80x160 color screen interfaced to the GD32VF103 through the SPI0 peripheral. Additional GPIO pins are used for chip select, reset and data/command mode.

The scope of this document is to explain the design decision,

constraints and architectural choices behind the Screen and Display classes that control the display.

2Pin Configuration

The Screen uses a ST7735S controller. The screen is interfaced directly with the microcontroller.

Illustration 1: Schematics

The CS pin unfortunately is not the SPI0 CS, so cannot be generated by hardware and must be controlled via software.

The RS pin as well must be toggled quite often. The SS7735S has a communication protocol in which a command byte is followed by a number of data bytes. In a typical draw operation there are at least four commands to be sent, requiring at least four toggles.

2.1MCU Peripherals

The GD32VF103 is equipped with two majestic DMA controllers for a total of twelve channels.

To minimize CPU use I can use the DMA0 to handle multi byte transfers from memory to the SPI0 peripheral, making the job of transferring pixel data that much cheaper for the CPU.

All of the DMA channels can steal up to 50% of the CPU main bus bandwidth, so some performance degradation can be expected on the CPU.

Illustration 2: GD32VF103 Peripherals

2.2Screen Configuration

The screen uses a 16bit RGB565 color space with 80x160 = 12800 pixels.

SPI0 has been tested up to 6.7MHz of speed.

Others modes are available but would take time to develop and not offer much savings. Current Screen and Display classes are good enough.

3Software Architecture

A lot of effort went into the design of the software, partitioning the workload and in deciding the ABI and HAL structures.

3.1Specifications

First thing to do is to understand my use case and what I want out of the Longan Nano screen.

Debug and profiling: Show things like voltages, currents, encoder readings, communication and errors.

Mostly ASCII characters: A fancy real time chart would be cool, but a waste of performance. I have the Raspberry Pi if I want to show fancy charts, and have more pixels and cpu to do so.

Low CPU and Memory footprint: I need the MCU to perform a fixed function. That's its primary objective. Debug and profile helps out and is secondary.

3.2Bandwidth and Memory Considerations

In order to refresh each pixel I need at minimum a 80x160x2x8=204.800 [Kb] transfer which yield a theoretical maximum of 32.8 [FPS], but would require the CPU to do nothing but line up bytes for the screen considering the prep time.

Any meaningful implementation needs a frame buffer, that for a full screen would be: 80x160x2 = 25.6 [KB] on an available memory of 32 [KB] meaning at minimum I would consume 80% of the working memory just for the screen.

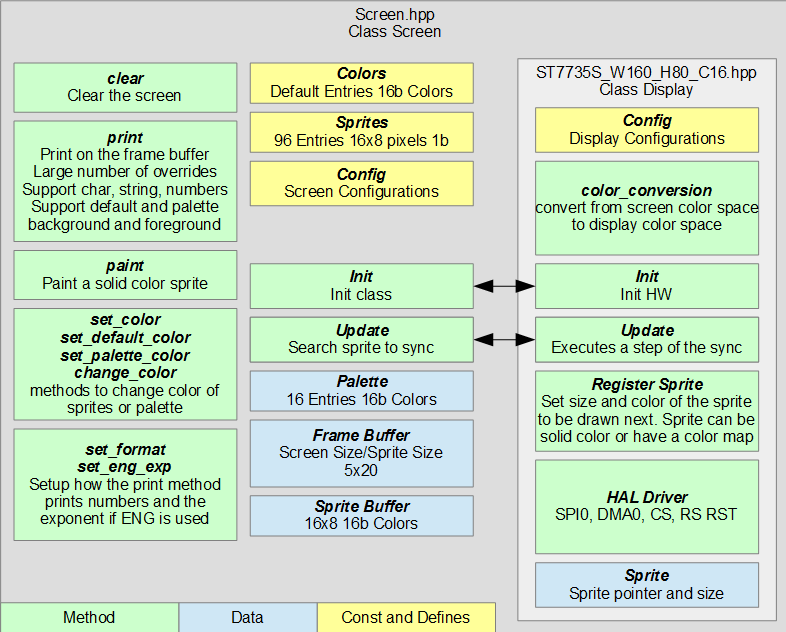

3.3Architecture

I made a sprite based library. This means that the screen only need a frame buffer as big as the biggest sprite.

I partition the driver in two:

Display Class: HAL and interface with the physical OLED. Provides sprite draw methods.

Screen Class: I abstract one level up and build all my sprite methods in a Screen class. All the print, sprite maps, frame buffer, etc... So if I change display, I can reuse the screen class.

The division means that I have two frame buffers. A frame buffer for the sprites that has the size of the number of sprites that can be drawn on the screen, and a frame buffer for the pixel data of a single sprite that is used for drawing.

Imagining a screen size of 80x160 and a sprite size of 16x8, this mean the frame buffer for the pixel data will be 16x8x2 = 256[B] while the frame buffer for the sprites will be 80/16x160/8 = 100 [B]. A massive saving in memory. Since I need to only show ascii characters anyway, this is not even limiting the flexibility of the draw too much. A drawback is that character are in a fixed grid, instead of being printable in each position.

The SPI needs time to send data, I can make the class asynchronous by returning after initiating the communication. I construct a core Update() method that returns without doing anything if the peripherals are busy.

This architectural decision means that the user will have to periodically call the update method, and it also means that the user decides how much resources allocate to the screen. If the user calls the update method slower than they are calling the print methods, simply some sprites won't be drawn.

Finally, I decide to split the update method in two. The Display::Update() is busy while sending a sprite, and idle otherwise. The higher Screen::Update() scans the frame buffer and register a sprite to send, then loops around the Display::Update() until the draw is complete. Since they are all non blocking calls, this reduces the CPU use to the minimum.

Another optimization is to have an update flag. Sprites are only redrawn if they have changed. This optimization costs an additional update frame buffer, but massively reduces bandwidth use when characters change sparsely.

Illustration 3: Display and Screen Class Architectures

4Conclusions

The Screen Class and Display class provide a ascii based frame buffer and support asynchronous control of the screen on board the Longan Nano board.

Extensive print methods allow to format numbers in a variety of ways for the library primary propose, which is to show fast updating debug information while using little CPU.

No graphics mode is supported as of now.

Future developments include:

Reduce idle use by using a pending counter

Improve the FSM of the display

Improve CPU use

5Source Code

Source code of the Demo application. Repository.

2020-08-02

2020-07-31 Longan Nano GD32VF103 Chrono Class and Scheduler

>>>Longan Nano GD32VF103<<<

>>>Longan Nano Chrono Class and Scheduler<<<

Chrono C++ Class uses the 64bit 27MHz systick timer to provide high resolution elapsed time and eaccumulate time HAL methods.

The Demo shows how to implement a fixed function scheduler with overrun and profiling using the Chrono C++ Class.

1Introduction

I use microcontrollers to perform fixed hard real time functions, in which a given list of tasks are executed always at the same rate in the same order, with little variation due to communication with the master.

With the AT4809 and previous microcontroller, I used an internal timer to issue the fast tick as an interrupt service routine, and from that tick, generate all the flags to execute slower tasks.

E.G. The PID running at 4KHz started by a fast tick at 4KHz, the LED running at 2Hz started by prescaling the 4KHz fast tick by 2000.

Illustration 1: Fast Tick issue execution of fixed tasks

With the Longan Nano I have a 64bit 27MHz fast tick timer at my disposal.

2Chrono Class

I decided to create an abstraction layer in class form since I'm practising with C++.

The class embeds two high resolution 64 bit timestamps.

The class uses scoped enums to encapsulate the configurations and definitions inside the namespace and class name e.g. the time unit is: Longan_nano::Chrono::Unit::microseconds

2.1Time Elapsed Mode

One of the core function of the class is to compute how much time has elapsed between two instants of time.

Use:

A timer has to be instantiated. Longan_nano::Chrono my_timer;

my_timer.start() followed by my_timer.stop() fill the timestamps. my_timer.get_elapsed( Unit ) returns the DeltaT between stop and start

my_timer.start() followed by my_timer.stop( Unit ) returns the DeltaT between stop and start

2.2Time Accumulation mode

Another thing the user may want to do is to integrate the time spent doing something to profile execution times or measure something happening in bursts.

The accumulation method has a special flag to use the internal 64 bit timestamps to do this integration at full sub microsecond resolution. This is much better than having the user integrate the rounded results of the elapsed time by hand.

NOTE: the 64bit operation needs a libc call. Use -fno-exceptions compile flag to avoid code size to blow up by 30KB for no reason.

Use:

A timer has to be instantiated. Longan_nano::Chrono my_timer;

my_timer.start() followed by my_timer.accumulate() fill the timestamps. my_timer.get_accumulator( Unit ) returns all the sum of all DeltaT occurred between start and accumulate

my_timer.start() followed by my_timer.accumulate ( Unit ) returns all the sum of all DeltaT occurred between start and accumulate

2.3Chrono Class Source Code

3Demo

This demo shows a practical implementation of an hardwired scheduler that issue the toggle of the RED led at 250mS, and the GREEN led at 750ms, by prescaling the fast tick for the RED led.

This scheduler monitors the overrun of tasks, and light a blue led if error occurs.

Illustration 2: Demo Tasks

Video 1: Demo Tasks

3.1Demo Source Code

Code for the demo to shows the hardwired scheduler, the prescaler, the overrun detection, the uptime measurement and the cpu time measurement.

4Conclusions

Time measurement and scheduling are fundamental to the operation of a fixed function hard real time microcontroller application.

In this document I laid out my solution and my implementation in the form of the Chrono class and fixed scheduler with execution flags. This solution does not use timer peripherals inside the microcontroller, perform unit conversion and works at full resolution and using C++ constructs.

This architecture will serve as the basis for all my applications based on the Longan nano GD32VF103.

2020-07-06 Longan Nano GD32VF103 PA8 and RTC Interrupts

>>>Longan Nano GD32VF103<<<

Illustration 1: Longan Nano test bench

1Introduction

The blink example went up quite painlessly, and I was also able to compile and execute the Bad Apple example that takes a stream of bitmap images from the SD Card and shows them on the screen.

With the basics out of the way, I focused on the interrupts.

1.1Arduino Framework Compatibility

The product page claims compatibility with the Arduino Framework, so I wanted to try the Arduino like interrupt handling.

Early on it was obvious that the Arduino framework has not been completed as the time of writing, with basic HAL functions like the digitalRead() empty. There was no hope of getting Arduino style interrupts to work without doing the framework HAL myself, so I dropped the thing.

2Interrupts

The Risc-V ISA specifies the interrupt handling as part of the core. Details about the ECLIC can be found in this excellent post from Kevin Sangeelee.

The GD32VF103 support an interrupt vector table defined as weak symbols in Start.S in the GD32 framework, it supports tiered priority where high priority interrupts can interrupt low priority ones and has hardware acceleration for them inside the MCU, on top of the special instructions and registers inside the core, as per Risc-V ISA specifications.

The GD32VF103 provides special interrupts from all sort of sources, including a reset vector, an error vector and a watchdog vector, on top of interrupts from almost every peripheral.

2.1Difficulties

Getting the interrupts to work was not easy.

In theory, all I had to do was to define a function with the same name as the symbol in start.S, and the C++ linker should have automagically linked the definitions by overriding the default .weak symbols.

After lots of testing, stack overflow came through with the answer: I need to use the keyword extern “C” to tell the C++ compiler not to change the name of the function and allow the linker to do its job and link the address of the interrupt service routine to the interrupt vector table.

3Example: PA8 EXTI

The Boot button is also wired to the PA8 pin. The EXTI in combination with the ECLIC is used to sense an edge on PA8 and trigger an ISR.

4Example: RTC Interrupt

The RTC timer is initialized to emit a “second” interrupt every 250ms. The interrupt toggles the RED LED.

5Conclusions

Interrupts are fundamental in an hard real time MCU application and the GD32VF103 is equipped with a refined system to handle interrupts.

This document shows how to generate interrupts from the EXTI and RTC. interrupts can be generated from all sort of sources, and there are even sources for reset, watchdog, errors, etc...

2020-07-05

2020-07-05 Longan Nano GD32VF103 Toolchain

1Abstract

My big 2019/2020 project, the Pi-Wars, was delayed due to Human Malware. With an additional year of development I decided to go back to the drawing board and expand the scope of the platform.

One of the aspects of OrangeBot I wish to improve is the motor controller. Shortcomings:

CPU: I hit the upper limit of the AT4809 8b 20MHz MCU running two 16b PID controller with two loops each at 2KHz, limiting the precision of the controls.

Current: No current loop in the PID controller. Adding one promises to optimize performance and efficiency

Auto-Tune: A PID auto-tuning algorithm based on light machine learning can optimize the precision of the PID. It can also compensate in runtime for changes in parameters to an extent (e.g. gearbox getting looser)

Screen: No screen on the motor board to quickly assess power, position and speed. Even error reporting relies on either a LED or the webserver. Clunky for debug

The decision was taken to upgrade to a new microcontroller.

1.1Why the Longan Nano GD32VF103

Given the additional time, I was in the mood to learn something new. Risc-V is gaining in traction, so I searched for a Risc-V based MCU. The 32b architecture already grant a 2X to 8X improvement to an 8b MCU for fixed point arithmetic, ensuring this would fix the lack of CPU power.

After some research, I found the Longan Nano. The performance are amazing for the price:

5$

32b 108 [MHz]

RV32IMAC+ECLIC

80x160 screen

In-circuit programmer

Reset+Button+RGB LED

Timer with quadrature decoder

The price to performance of the platform is AMAZING, and the feature set allows for everything I need to include in the motor controller.

One of four advanced timers allow to decode in hardware the encoder reading, without relying on costly ISR decoding, I have ADC channels for current reading, DMA, communication, and much more. Adding a screen for 5$ is incredible. They threw in a cheap plastic case for good measure and a couple of pin strips.

In the end I paid about 10€ per board considering import duty and delivery.

Illustration 1: Longan Nano

2Example

The Longan Nano comes in with a preloaded video player example. It requires an SD card with a video encoded as sequence of BMP images.

Video 1: Longan Video Demo

3Toolchain

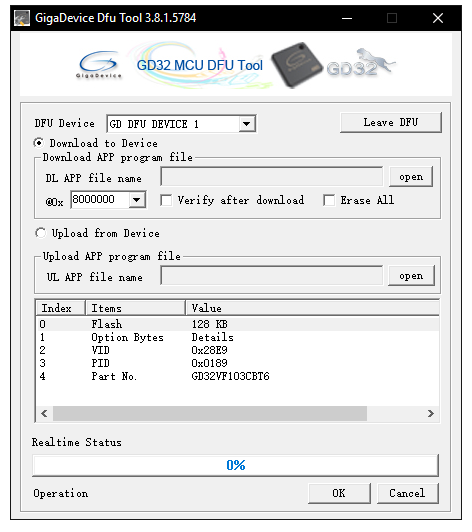

With the physical boards arrived and tested, it was time to write and load code.

3.1VSCode + Platform.IO + Longan Nano Toolchain

The toolchain is well explained in this tutorial.

It requires GIT installed if you don't have it already.

Illustration 2: Platform.IO Installed

Unfortunately, that's the only thing explained well and I run into many problems making the toolchain work.

For the bootloader, you need drivers.

That's not all. In order for the board to show up, you need to:

Press the boot button (top button)

While boot is pressed, press and release the reset button

Release the boot button

This makes the MCU enter programming mode, allowing it to show up on the Gigadevice GD32 MCU Tool. Always check verify. The firmware to be uploaded is the .hex stored in the .pio\build\sipeed-longan-nano subfolder of the project.

Illustration 3: DFU Firmware Upload tool

I was unable to make DFU tool work with the one click upload feature of VS Code, but its not a big deal to upload manually. It might be possible to use the serial port and a serial port adapter with a bootloader to use that feature, but I have yet to try, and USB-C is convenient apart from having to use the button combination to get the board in programming mode.

3.2New Project

With the toolchain in place, its time to start coding. On new project, you can select folder and framework. Use a custom project folder and Arduino framework.

Illustration 4: New Project

You have a choice of two framework. The GD32 framework doesn't work and I was unable to get to work. The Arduino framework can run the blink example. And nothing else. Even DigitalRead is not coded in the HAL Arduino library.

What does work is to use the Arduino framework write a main, and just use the functions in gd32vf103.h. From here you can pick my barebone example that should work with interrupts.

From now on, you can compile a project with VS Code and upload with DFU tool on the Longan Nano board.

4User Library

Like I did for other microcontrollers, I'm going to slowly build up upon the base HAL to have convenient driver and file structure for new projects.

I plan to use C++ classes whenever makes sense, and have a basic IO configuration init procedure and examples for how to do stuffs right. Lightweight screen drivers, initialize timers in various modes, hardwired scheduler, etc...

4.1Examples

Unfortunately the Longan Nano has few examples and bad documentation.

There are examples for other evaluation boards and GD32 MCUs to help draw the drivers of the various peripherals, but it takes work to adapt them and make them work.

Video 2: Longan Interrupt Example

4.2Interrupts

The interrupts were very hard to make work.

Here the solution from stack overflow.

The Risc-V has a very refined interrupt controller compared to the MCU I'm used to. The ECLIC is and extension and part of the Risc-V instruction set of the MCU. It provides special registers and instructions.

The ECLIC is interfaced with other controller like the EXTI to provide an extensive tiered interrupt support. There are also vectors to handle exceptions, watchdog, etc...

I feel it'll take time to master its use.

5Conclusions

The Longan Nano is a powerful 32b Risc-V MCU that fits the use case of the OrangeBot control board perfectly. Despite the clunkiness of the toolchain and lack of documentation, the cost and feature set provide great value and I consider it a great entry point to learn 32b MCUs and Risc-V.

2020-05-08

2020-04-18 OrangeBot Motor Swap

>>>Pi Wars 2020<<<

1OrangeBot Motor Swap

By design, OrangeBot was meant to be powered by four DC motors and have a top speed of 20 [Km/h]. Supply shortages meant that the only motors available were capable of either 10 [Km/h] or 30 [Km/h].30 [Km/h] motors were ordered and installed, but during the design stage, the torque needed to turn with a four wheeled platform was not accounted for. This caused two severe problems:

- Torque was insufficient to turn

- Motor gain was too high

1.1Torque

In order to turn a platform with four fixed wheels, a torque is required to make the wheels slide on the terrain sideways. It was impossible to solve this issue even with overvolting the 12 [V] DC motors, and it was impossible to source new slower stronger motors in time for the competition. The scope for the platform was reduced, and OrangeBot is now equipped with two DC Motors and one pivot wheel.While this allows OrangeBot to turn, the torque was further halved, impeding acceleration and climbing performance.

1.2Motor Gain

The motor had too much gain in terms of [mm/s/V]. PWM controls were unusable, and the PID controller had an impossible job.Encoders were upgraded from low count magnetic to high count optical, giving the PID a better chance. After months of work, a two loop PID controller with integral speed reference running at 2 [KHz] and consuming all available computational power on the microcontroller was finally able to suppress ringing and instability and achieve a controllable platform even under the effect of the large inertia.

The motors were highly stressed by continuous fine motion inversion, but the performance were Pi-Wars grade.

2Motor Swap

With additional time, it became possible to just source motors better tuned to the task.The original motors have a speed gain of 613.9 [mm/s/V], a force gain of 14.04 [g/A] and an encoder scale of 15.79 [cnt/mm] thanks to the high resolution replacement quadrature optical encoders.

Replacement Motors

The replacement motors have a gain of 185 [mm/s/V], a force gain of 28.18 [g/A] and an encoder scale of 0.9639 [cnt/mm].

Note that with the original motors, the torque is low enough that the drag significantly affect top speed. With a drag of 0.001, top speed is about 32 [Km/h]; With a drag of 0.02 top speed lowers to 15 [Km/h].

2.1Uninstall Motors

Uninstall old motors:- Remove wheels by unscrewing them from the Hub

- Remove Hub

- Disconnect the power and the encoder wiring from the Main

Motor Board

- Unscrew the motor from the motor bracket

2.2Uninstall Motor Brackets

The replacement motors are longer. Motor Brackets have to be uninstalled and new holes have to be made to fix them to the structure.The interaxis with the replacement motors is still compatible with Pi-Wars specifications, but is getting dangerously close to the 225 [mm] limit.

2.3Re-Install Motor Brackets

New holes are made for the M3 bolts that hold the motor brackets in place.A task for the future might be to cut new plates using a laser plotter, but for now focus is on achieving the target performance. Optimization of workable if sub-optimal features will be left for later.

2.4Install Replacement Motors

Installing the motor is straightforward. The power wiring of the motors were replaced with higher gauge prior the installation, the encoder wirings was cut to size in this step.2.5Solder connectors

Power wirings are soldered with a tip. Encoder wirings are soldered with an L 2.54 [mm] pin strip.Main Motor Board

2.6Assembly

Assembly the hubs, wheels and the platform back together.3Testing and Calibration

3.1Power Test

The platform powers up without problems3.2PWM Remote Control Test

Test PWM controls. Thanks to the reduced speed and increased torque, OrangeBot now controls just fine in PWM mode, with the only drawback of not going in a straight line.3.3PID Calibration and PID Remote Control Test

A quick calibration of the PID through the remote controls was enough to get good closed loop performance and have the platform move in a straight line.4Conclusions

The replacement motors have more torque and less speed, allowing OrangeBot to be stronger and more precise.There are other design decisions and mistakes made to achieve the deadline of 2020-03-29. With the deadline moved to 2021-03, many of those decisions can be revisited, to achieve an higher quality design.

2020-03-06

2020-03-02 Turret Construction

>>>Pi Wars 2020<<<

1Turret and Main Weapon

With the completion of the high speed controls and low latency video streaming, the stage is set to proceed with the final phase of construction of the OrangeBot platform.This is the biggest upgrade since the construction of the core platform, and beyond this point only minor adjustments should be required.

Mechanical upgrades:

- Component fitting and Pi-Wars specification check

- Turret

- Main weapon

- Rotation and Elevation mechanism

- Attachments:

- Pi-Noon Hard Point and Pi-Noon melee weapon servo

- Lava Palaveer sensors

- Eco Disaster forklift

- Pi-Noon Hard Point and Pi-Noon melee weapon servo

- Battery Strap

- Maintenance hatches

- Servos: Electronics, connectors, cable management and power

- Power: Main switch, distribution, cable management, turret

joint routing

- Raspberry-Pi: Power, I2C and UART proto hat

- Sensors: I2C network

- LED swag!

- Servo driver and messages

- Main weapon driver and messages

- Forklift driver and messages

- Pi-Noon lance driver and messages

- Key bindings

- Integration of all remote controls in the client HMI

1.1Disassembly

The platform was disassembled in preparation for the upgrade.Electronics need minor modifications and many new cables needs to be routed.

1.2Obsolete Plates

The now obsolete “platform top plate”, “turret base plate” and “turret rear plate” needs retiring as they were place holders.2Main Electronics

Main board has to be upgraded to support:- Three servo motors

- Switch (Main Weapon Feedback)

- Third DC Motor (Main Weapon Spring)

Unfortunately testing revealed that three full sized servos cannot be powered by the main board and require a second independent 5V3A power regulator, that was cannibalized from “Maze Runner”.

2.1Main Weapon Test

A key decision for the next phase of component fitting was whatever the main weapon could be mounted side ways or needed to be mounted up strainght.3Turret Construction

With key decisions about the design taken, construction could move to the next phase.3.1Turret Mockup

A Mockup of the turret mechanism was made to take measurements on the size of various plates and decide on the component placement and fitting.3.2Turret Rotation

With the elevation mechanism and turret dimensions sorted out, it was time to go back to the original design and evaluate the place holder rotation mechanism.The rotation is critical as it has to withstand the inertia and shock of the moving platform and has to be reliable. After careful consideration, it was decided to retire the previous mechanism and redo three plates.

The rotation joint was also moved more toward the rear of the platform. This has the benefit of looking better (swag first!) and granting better clearance to both the components inside the platform and inside the turret.

There were two ways to place the rotation joint. As Murphy dictates, the wrong way was chosen initially!

3.3“Top Plate” and Rotation Joint

A new top plate was constructed to accommodate the rotation joint mounted in reverse. The holes to fix the top plate to the platform were reduced from eight to four, with a fixed bolt and a space below them. This allows for easier maintenance, as removing four bolts allow the turret, the top plate and the rotation mechanism to come off in one piece. An air gap is maintained to get some airflow inside the platform in case thermals become a concern.3.4Rotation Mechanism

It was very important to take extra care in the design and construction of the “Rotation Mechanism” as this servo and joint have to tank the rotational inertia of the turret caused by the motion of the platform.A “Rotation Key” transmit the motion from the servo, through the hollow hole of the “Rotation Joint” up to the “Rotation Plate”. The key itself can be moved upward to disconnect the servo from the turret quickly for maintenance.

The “Rotation Plate” will feature additional holes for the cables to pass from the turret to the platform.

3.5Turret Component Fitting

Another critical component of the design is the “Turret Base Plate”. It's important to get the dimension and placement of the holes right as all other turret plates and components use this plate as base.3.6Turret Elevator Plate

Because so much of the fitting depends on the elevator mechanism, the first turret plate to be finalized was the “Turret Elevator Plate”.- Raspberry Pi

- Main Weapon

- RaspiCam

- Targeting Laser

- Elevator Joint

3.7Turret Base Plate

With the design of the turret validated, the Turret Base Plate could finally be prepared and placed in position. The Rotation Joint was quickly tested and proved to perform flawlessly, achieving a great coupling between turret and the rotation servo below.3.8Elevator Joint

The elevator joint is constructed from Lego Technic components and M3 bolts. Lego makes it much easier to build a rotating connection. The elevator joint connects the “Turret Elevator Plate” to the “Turret Right Plate” and “Turret left Plate”.The main weapon is connected to the Turret Elevator Plate by means of an L shaped structural element with two M4 bolts.

3.9Turret Top and Rear Plates

The Top and Rear plates are straightforward. They just needs holes for the L shaped structural elements.3.10Turret Final Assembly

The “Turret Left Plate” was the last to be constructed, and accommodates the “Elevator Servo”.The Elevator Servo is connected to the bottom of the “Turret Elevator Plate” with a beam made from a clips and held in place by M3 bolts.

4Conclusions

With the completion of the turret, the platform is finally nearing completion.The platform dimensions:

Width: 190 [mm]

Length: 260 [mm]

Height: 310 [mm]

Weight: 3811 [g]